Purpose of Test

This fiber analysis test provides individual procedures for the quantitative assessment of moisture content, non-fibrous content, and fiber composition of textiles.

This test uses different analysis methods to identify fiber composition, including:

- Mechanical

- Chemical

- Microscopial

The test method is recommended for various blends of fiber:

Natural Fibers:

- Cotton

- Hemp

- Hair

- Ramie

- Linen

- Silk

- Wool

Man-Made Fibers:

- Acrylic

- Acetate

- Modacrylic

- Nylon

- Polyester

- Rayon

- Olefin

- Triexta

- Spandex

Terminology Defined

Fiber Analysis – The method of identifying and analyzing the fiber used on the textile.

Clean Fiber Content – Amount of fiber after the removal of all non-fibrous contents.

Moisture Content – The amount of moisture present in the fiber.

Non Fibrous Content – These include fiber finishes, yarn lubricants, fabric softeners, starches, waxes, oils, soaps, and more non-fiber materials that were added to the fabric.

Fiber Composition – The composite materials that make up the fiber textile.

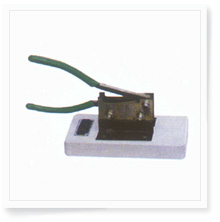

Fiber Cutter – A cutting tool with two razor blades, an assemblage and a threaded pin that hold the blades in position.

Dissolving Agents – The liquid substances used in the test to dissolve the fiber.

Materials Used for Test

- Test Specimen

- Analytical Balance

- Oven

- Dessicator

- Soxhlet Extractor

- Constant Temperature Bath

- Weighing Bottle

- Erlenmeyer Flask

- Beaker

- Filtering Crucible

- Suction Flask with Adapter

- Microscope

- Projection Microscope

- Fiber Cutter

- Wedge Scale

- Required Chemicals

Testing Procedure

The test methods for the quantitative analysis of fiber include:

- Moisture Content Test

- Non Fibrous Content Test

- Chemical Analysis Test

Test Procedure (Summary)

Moisture Content Test

Part 1: Preparation of test specimen: The test specimen is collected and weighed on a balance. It will be dried in the oven under certain conditions and temperatures.

Part 2: Cooling of the test specimen: After a given period, the test specimen is removed from the oven and allowed to cool at room temperature.

Part 3: Repeating the process and reweighing. The heating and cooling process is repeated then the fiber is reweighed. Standard calculations are used to identify the moisture content.

Non-Fibrous Content Test – Clean Fiber Content

Part 1: Preparation of test specimen: The test specimen is dried in the oven under certain conditions that differ depending on the kind of textile treatment applied.

Part 2: Wetting and drying of test specimens: Depending on the treatment type, the test specimen will be wetted with different liquid solutions, dried, rinsed, and dried again under certain conditions.

Part 3: Calculation: Standard calculations are used to identify the non-fibrous content of the specimen.

Chemical Analysis Test

Part 1: Preparation of test specimen: The test specimen is dried under certain conditions and weighed.

Part 2: Adding dissolving agents: Certain amounts of dissolving agents are added to the fiber and then dried again at certain conditions.

Part 3: Calculation: Through the use of standard calculations, the fiber analysis is completed.